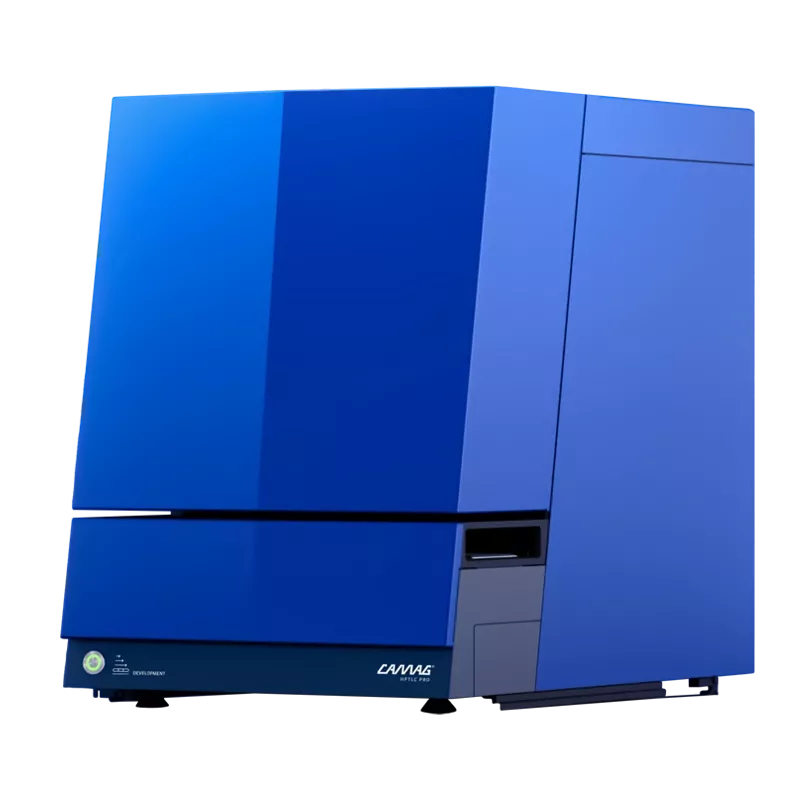

HPTLC Software visionCATS

Request consultation

In a nutshell

HPTLC analysis – made easy

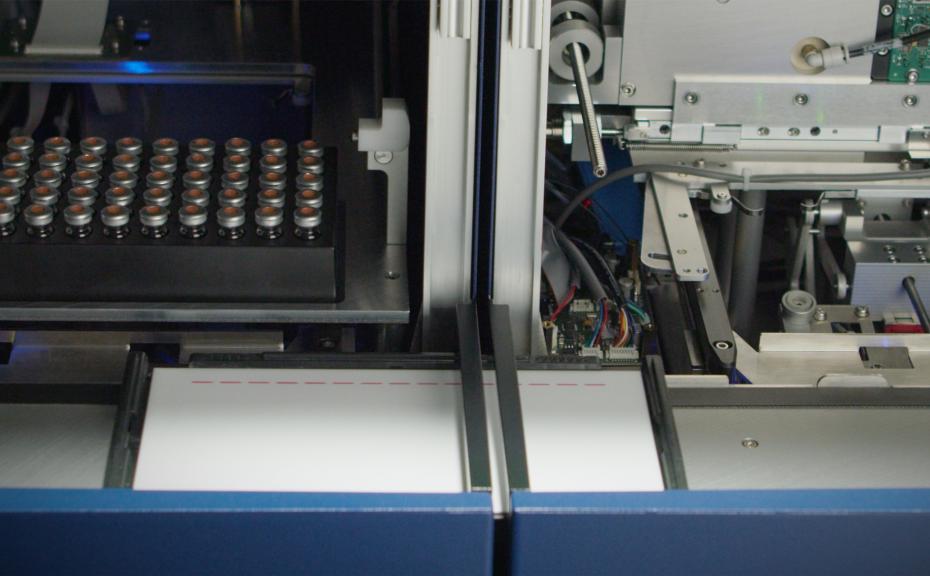

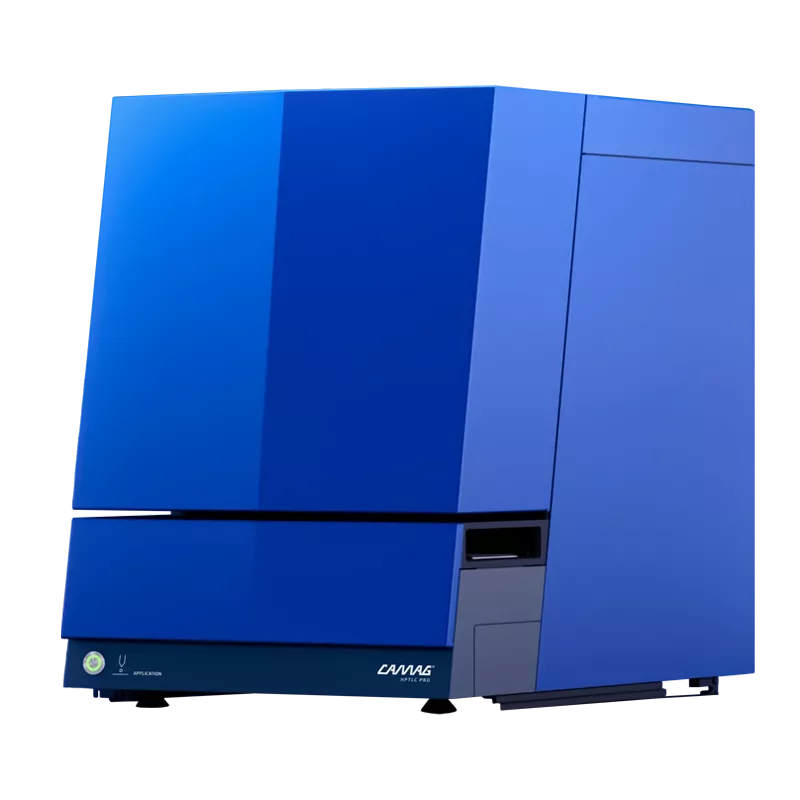

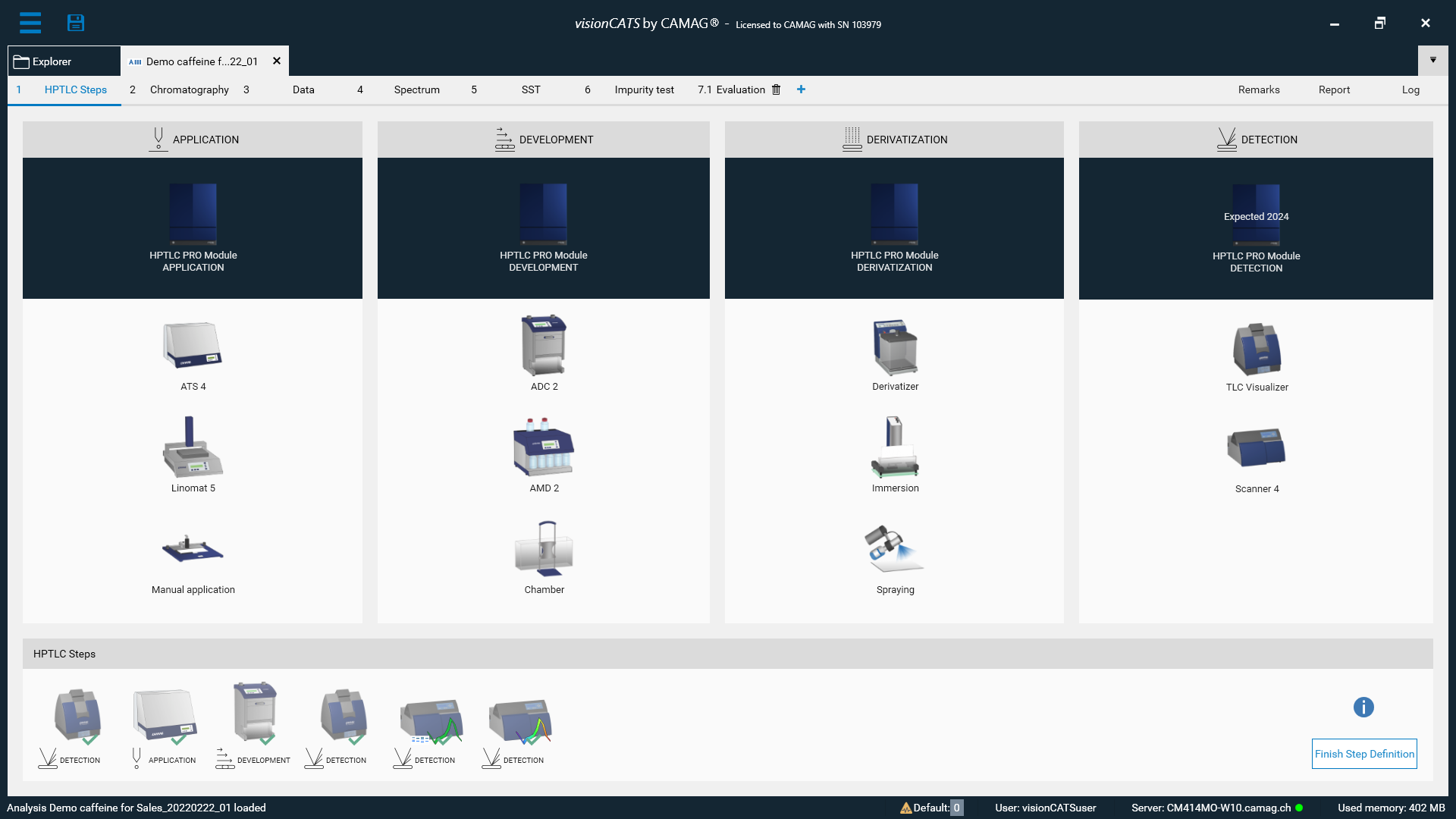

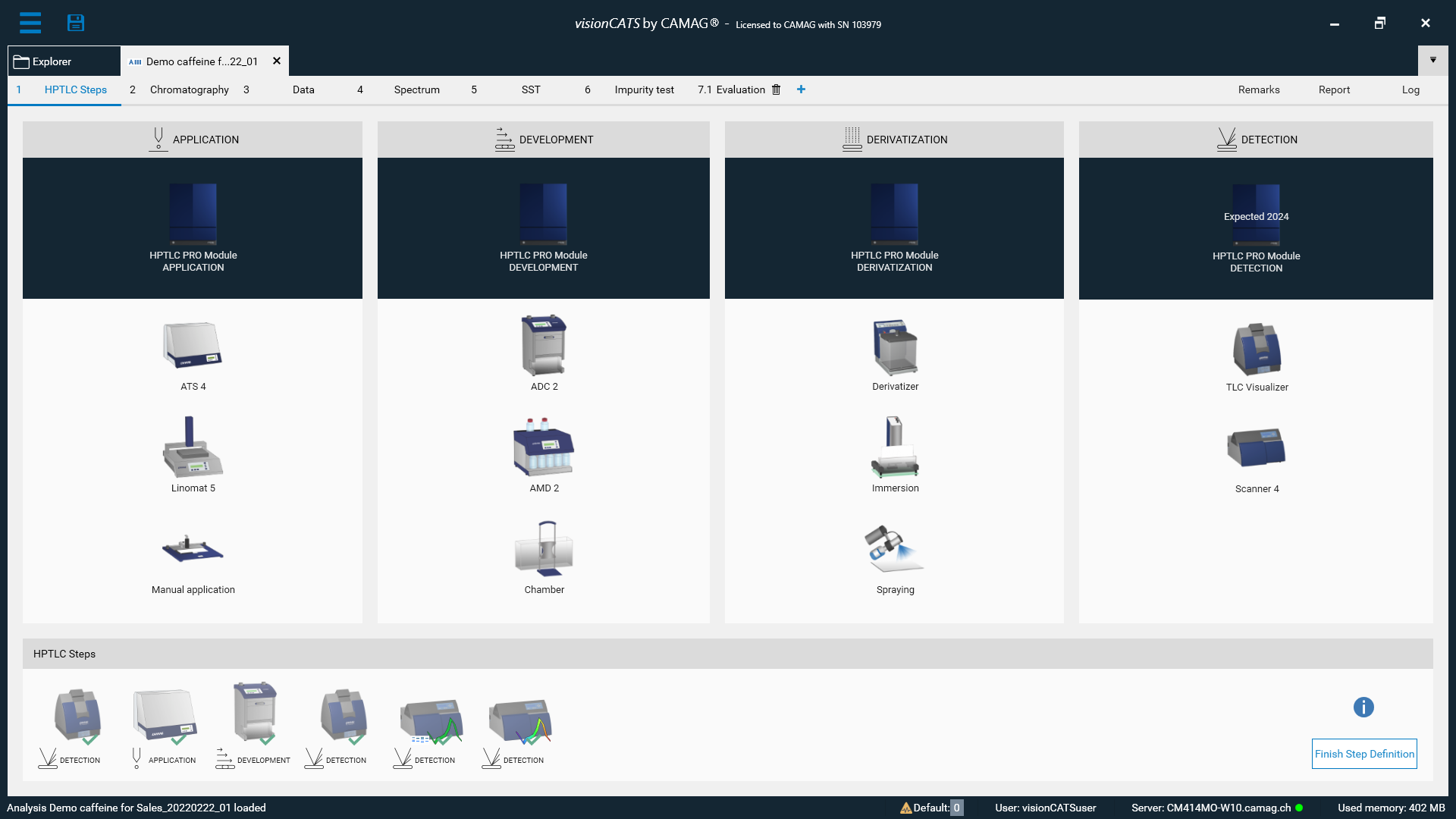

visionCATS is built for simplicity and intuitive operation, streamlining the entire HPTLC workflow by controlling both HPTLC PRO Modules and HPTLC instruments while efficiently managing data.

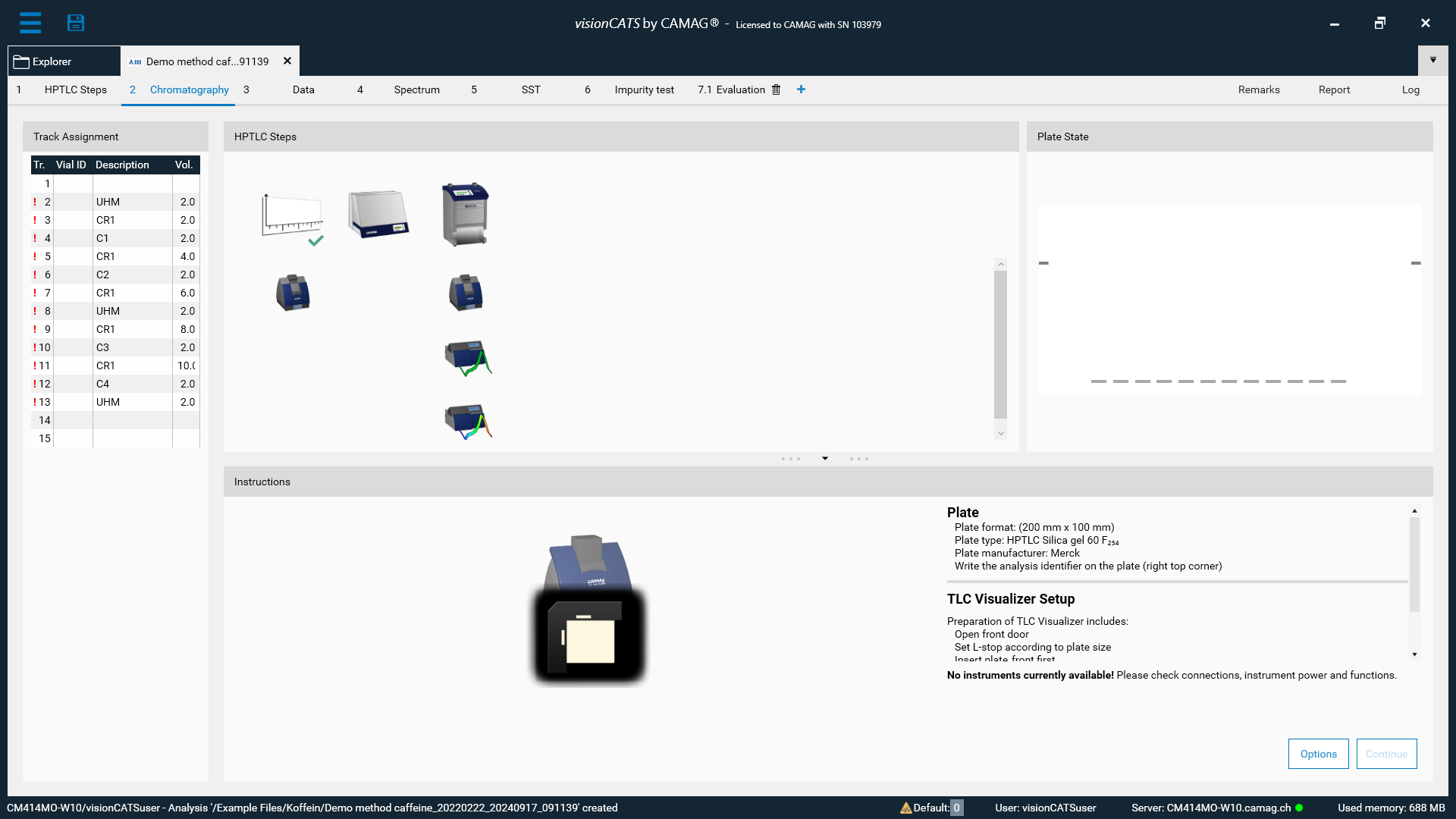

With its user-friendly interface, visionCATS guides users smoothly through the entire chromatographic process, from sample setup to report generation. Starting is easy—select a default method, fill in the sample table, choose a developing solvent, and select a derivatization reagent. Detection parameters can be customized as needed, and visionCATS leads users through each step.

Creating custom methods is equally straightforward. Users can easily select the required steps, and the sample-oriented design enables the creation of virtual plates by combining tracks from different plates. This feature is especially useful for batch-to-batch comparisons and long-term stability testing.

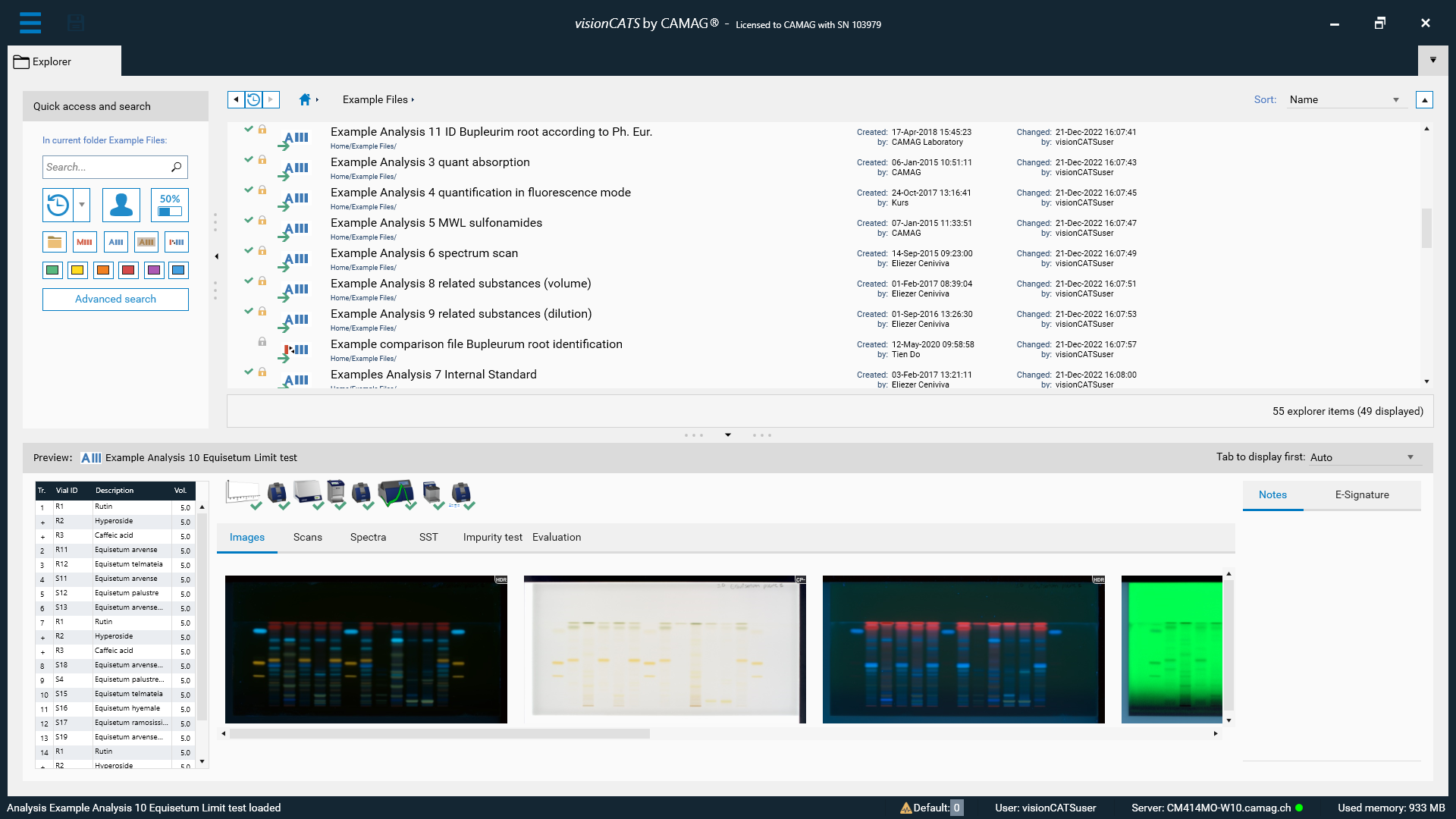

Finding relevant samples is made faster with a robust search tool in the file explorer. Users can search by text, date, samples, methods, or analysis files, with extended preview options. Custom search filters can also be created, allowing for even more streamlined navigation and data retrieval.

Key Features

-

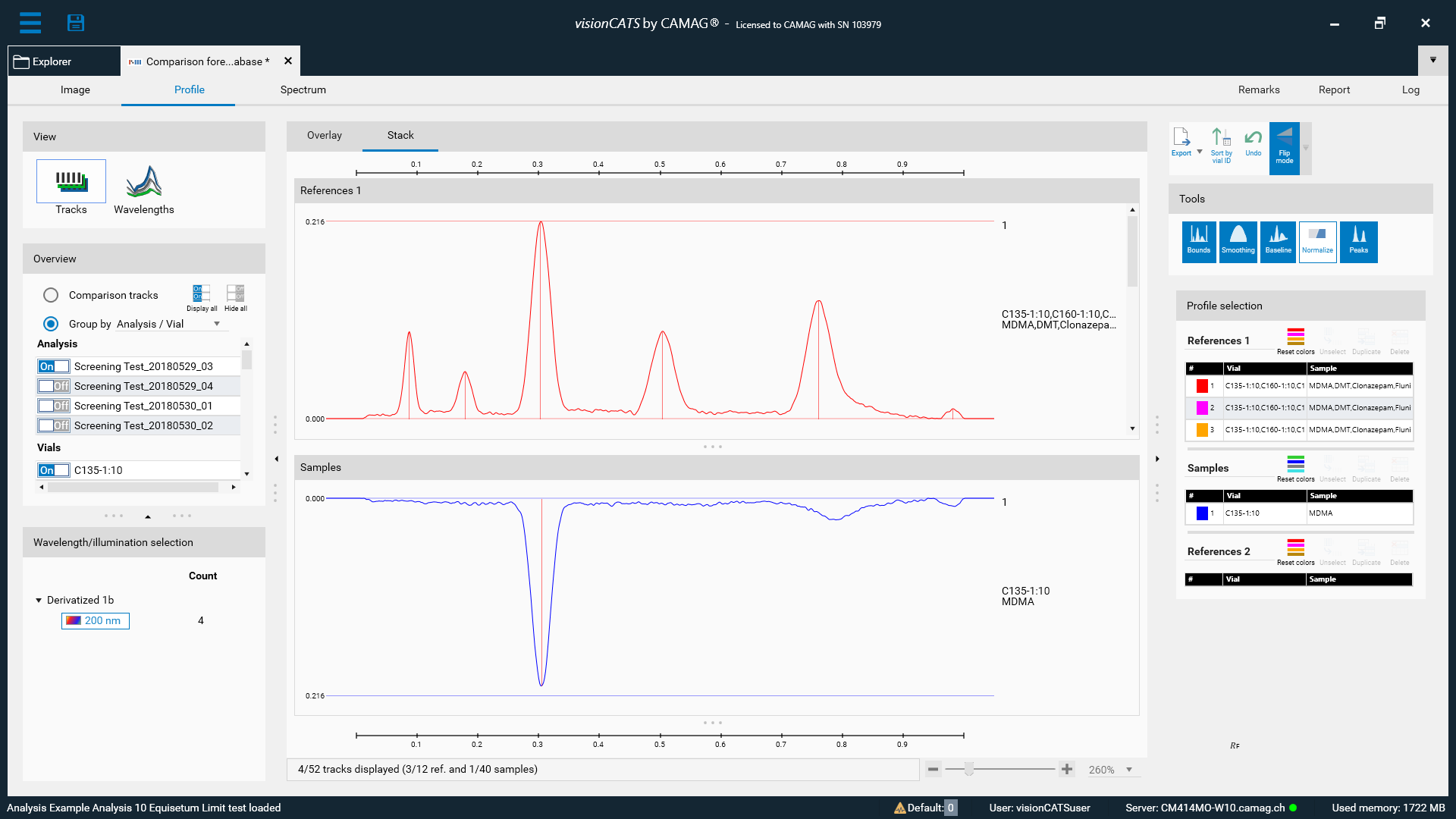

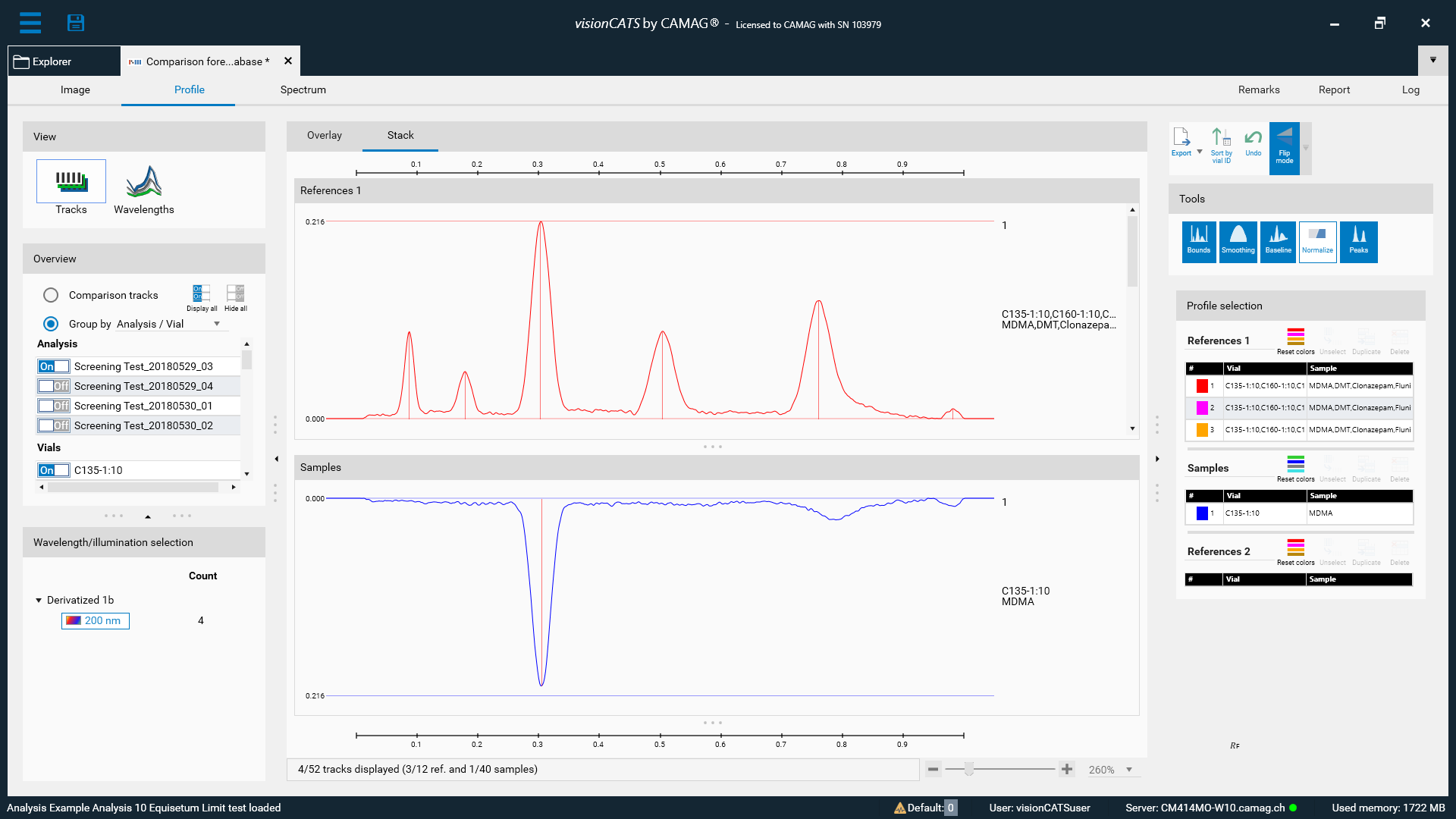

Comparison Viewer

With visionCATS integration, the TLC Visualizer 3 allows extraction and export of selected sample data from acquired images for easy comparison. References and samples from the same or different plates and detection modes can be displayed side by side, ensuring full traceability of all data for regulatory compliance.

-

Image Enhancement Tools

visionCATS supports low-noise, high dynamic range (HDR) imaging and allows to edit images acquired with the TLC Visualizer 3, offering a set of enhancement tools. Sophisticated algorithms guarantee the highest image quality for identification of even the faintest zones.

-

Scanning Densitometry and Spectral Evaluation

Following their chromatographic separation substances on the plate can be measured by Scanning Densitometry using the TLC Scanner 4. Recording of UV/VIS spectra and their comparison with reference spectra allows identification and comparison with spectra from reference libraries.

-

Quantitative Analysis

Five quantification functions, including linear and polynomial regression, are available for determining substance concentration after densitometric or image-based analysis. Multiple scans and up to five evaluations can be performed within a single analysis file.

-

HPTLC Method Library

For seamless import of validated methods and images of standards and reference materials, visionCATS provides a free of charge HPTLC Method Library for licensed users.

-

Regulatory Compliance

visionCATS HPTLC software ensures regulatory compliance by supporting GMP/GLP guidelines and 21 CFR Part 11 requirements. With audit trails, user access controls, and electronic signatures, it secures data integrity and traceability, making it ideal for regulated environments.

HOW IT WORKS

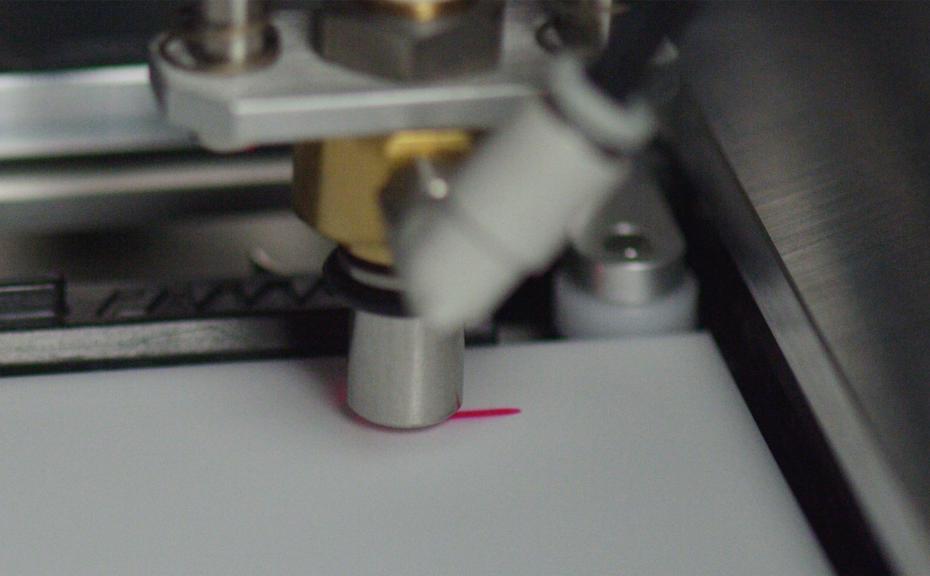

SMOOTH & PRECISE OPERATION

-

HPTLC Analysis – Made Easy

01

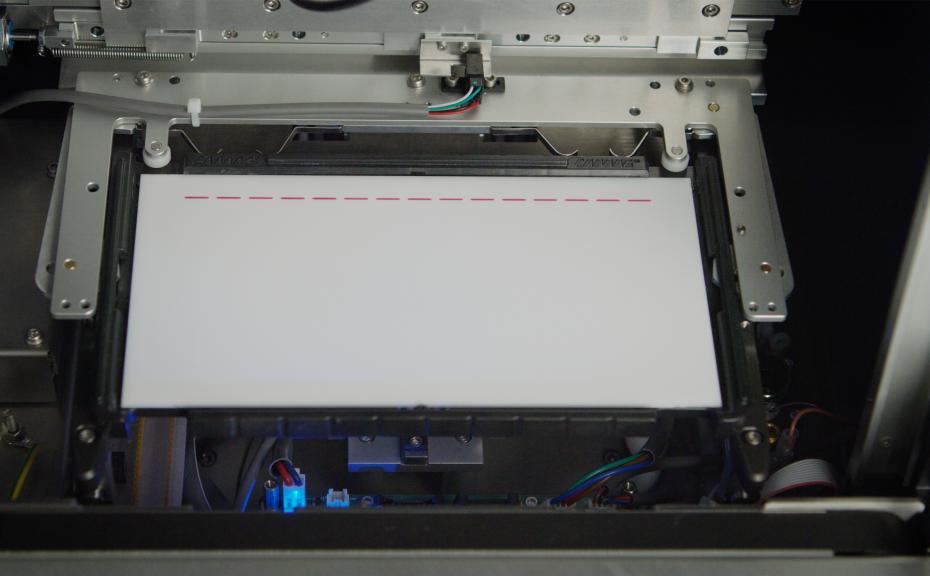

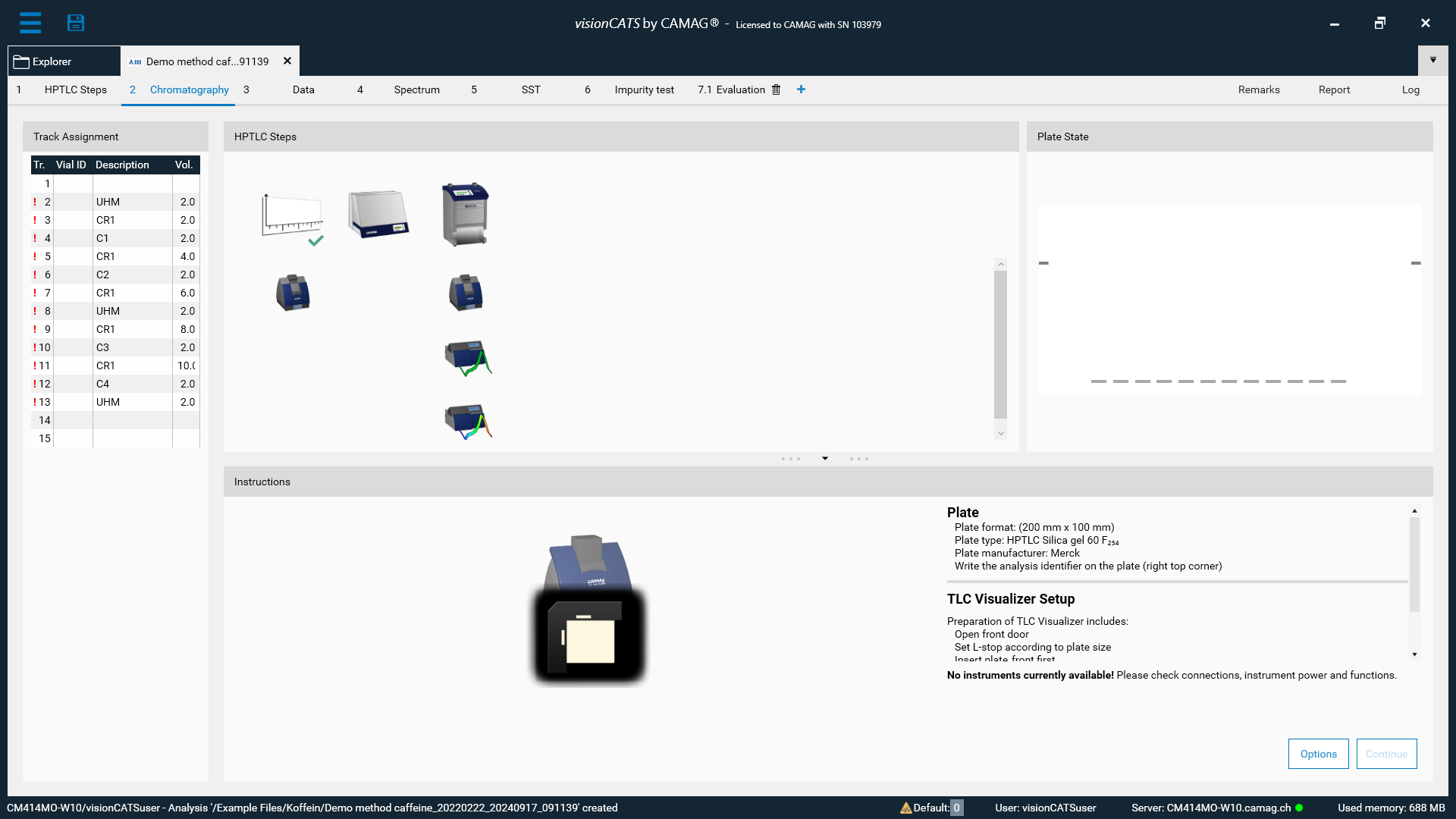

HPTLC Analysis – Made Easy: Create your own method with a few mouse clicks.

-

Guided Analysis

02

Guided Analysis: Select a method and visionCATS will guide you

-

Sample View

03

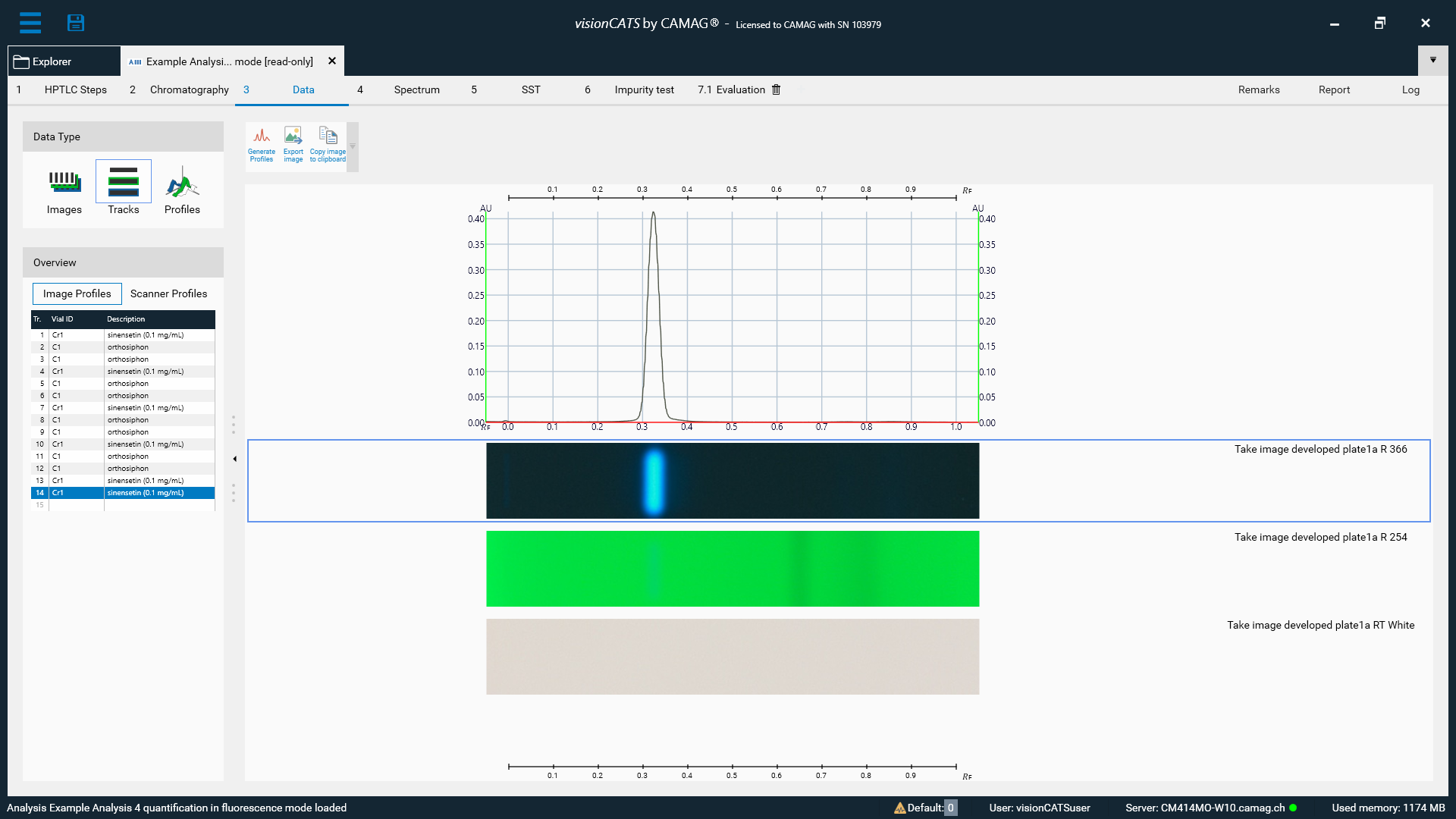

Sample View: All available data related to the sample are displayed

-

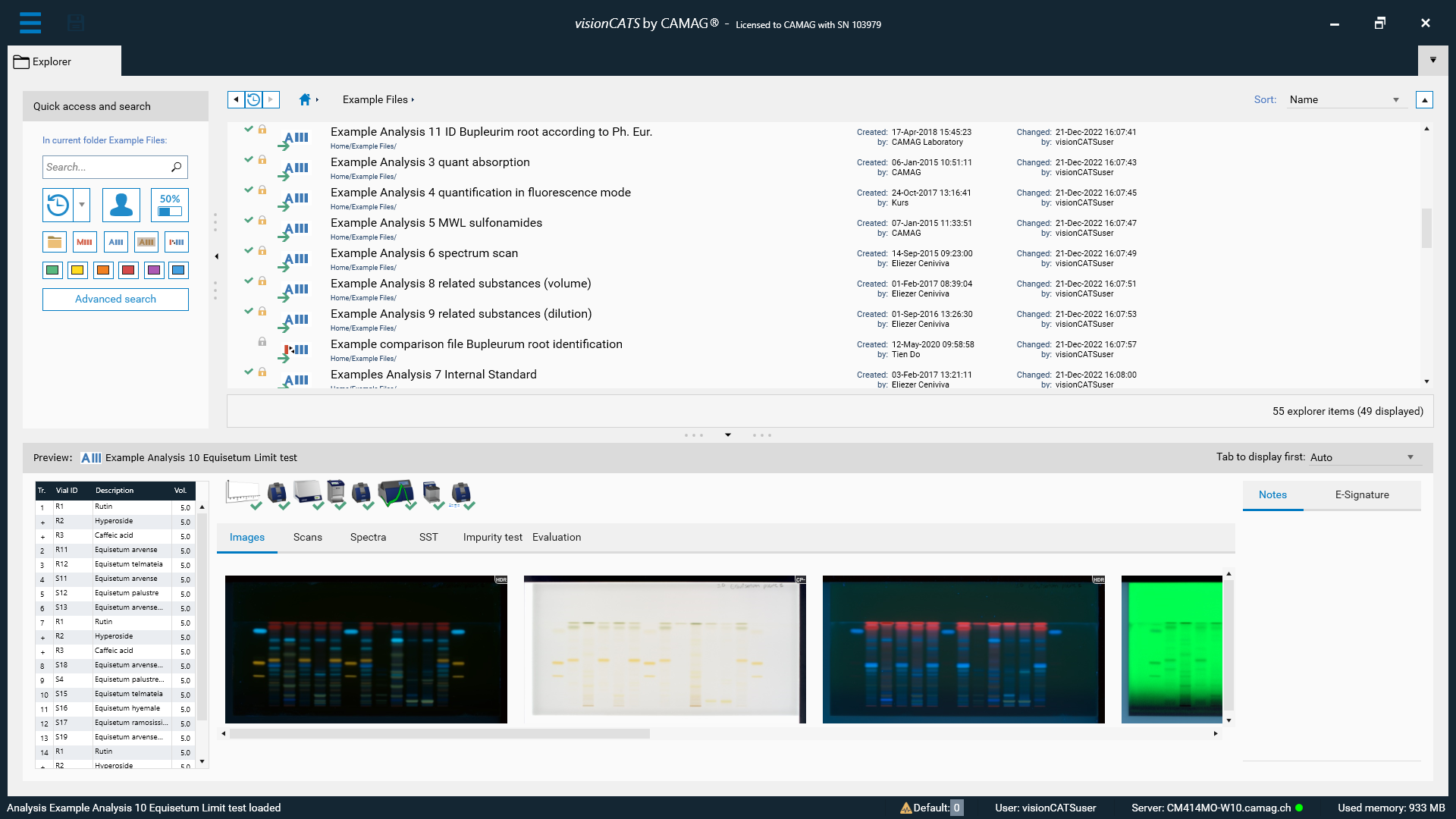

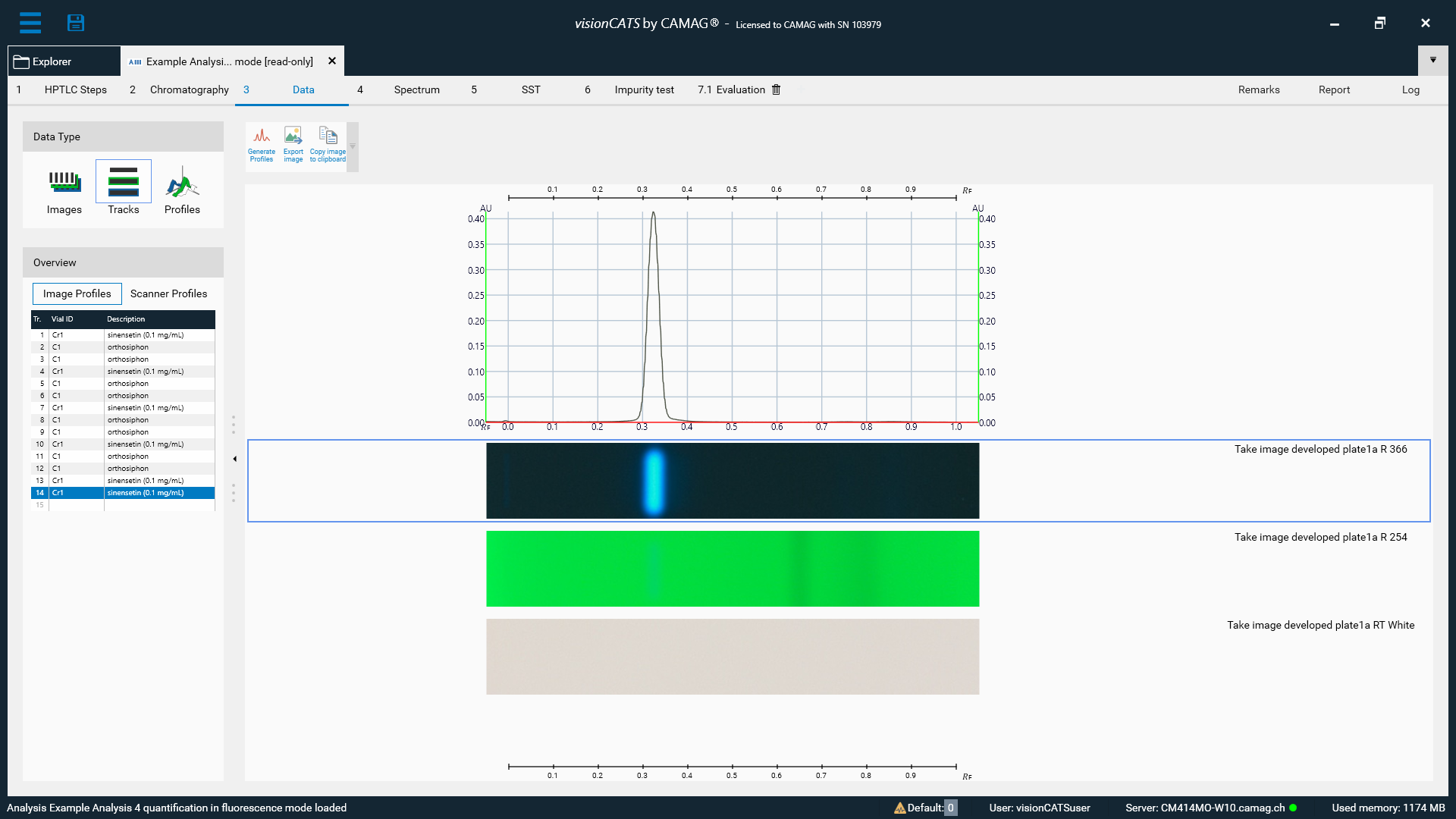

Data Preview

04

Data Preview: Provides an overview of steps and samples of an analysis or method

-

Profile Comparison

05

With visionCATS, it is possible to compare profiles of samples developed in different analyses.

Comparison & Enhancement Tools

DOCUMENTATION WITH

TLC VISUALIZER 3

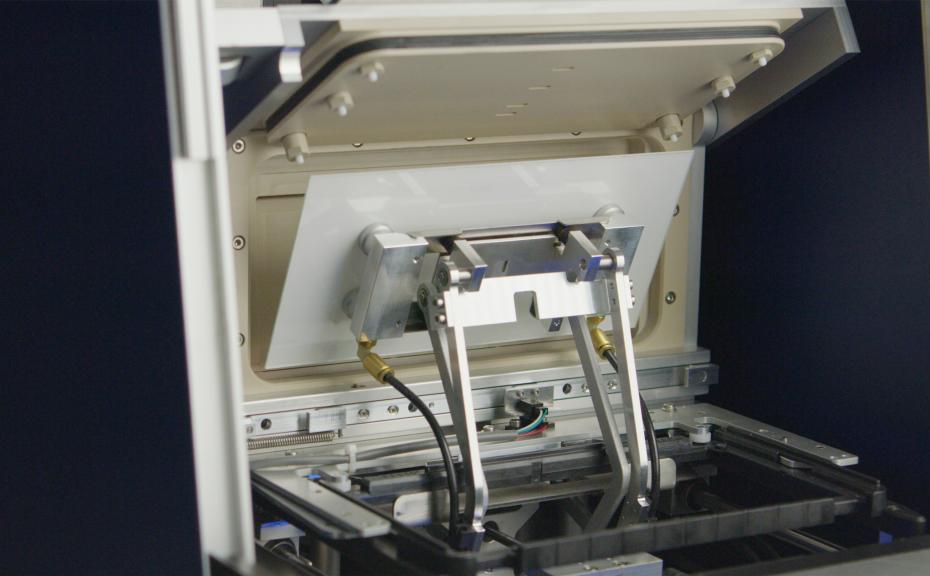

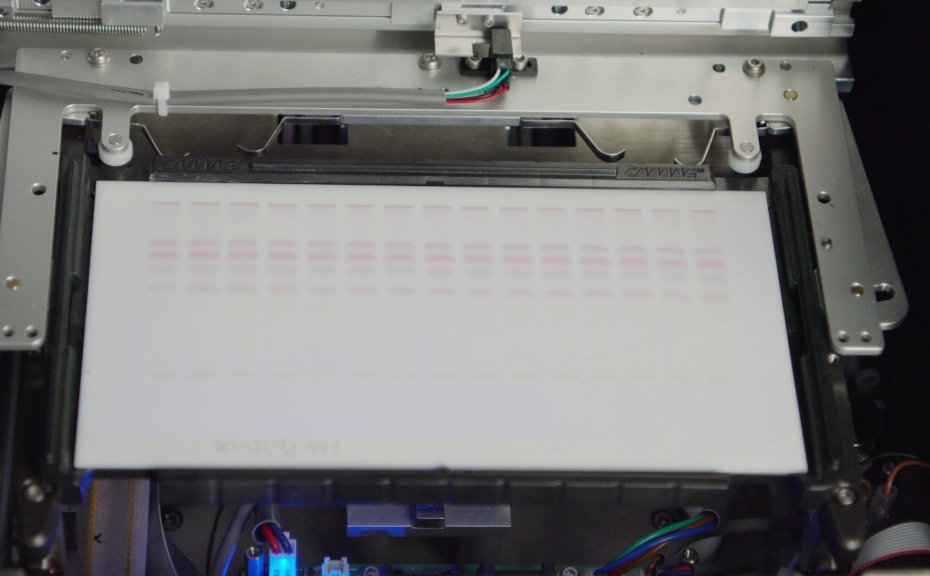

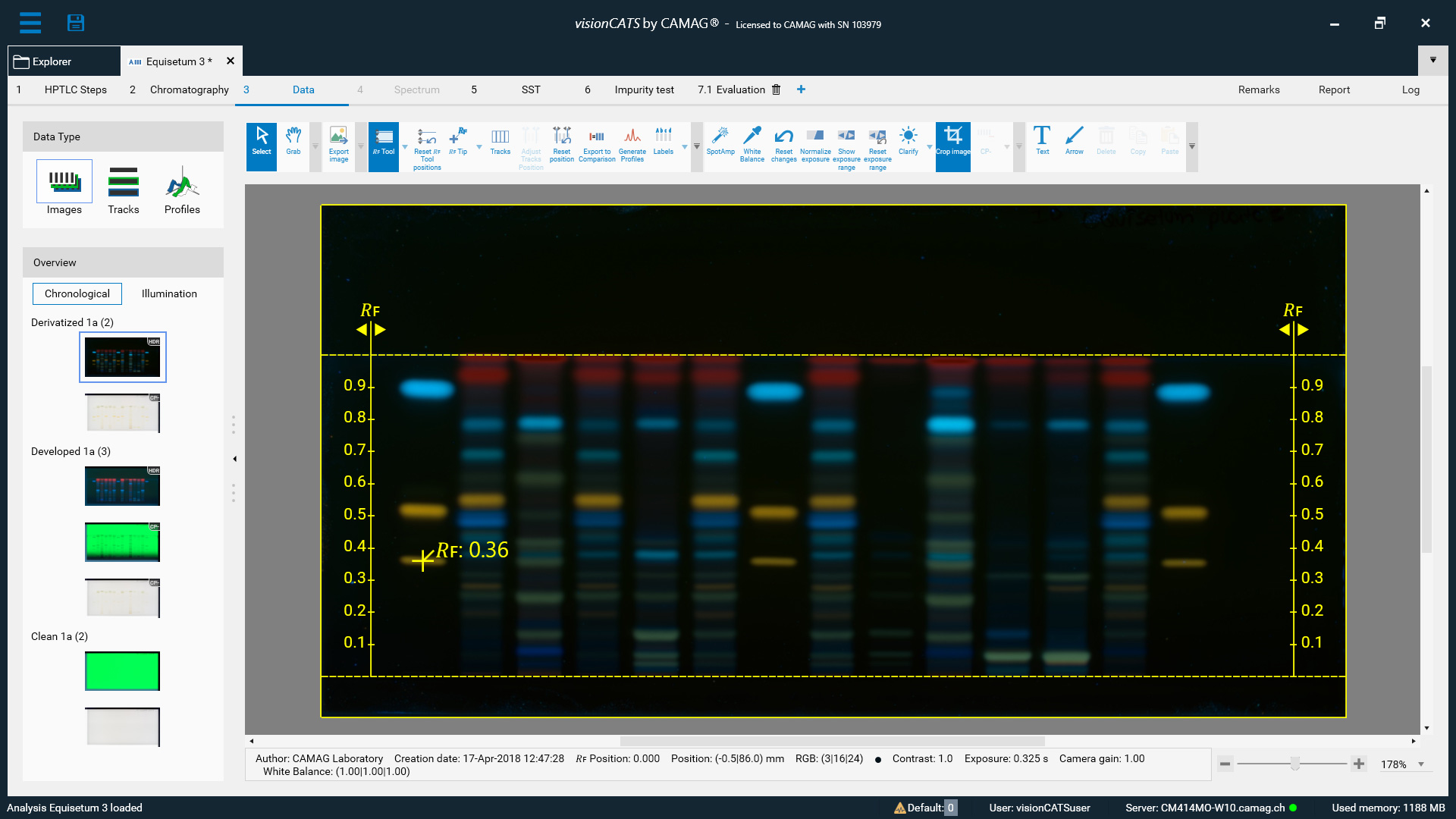

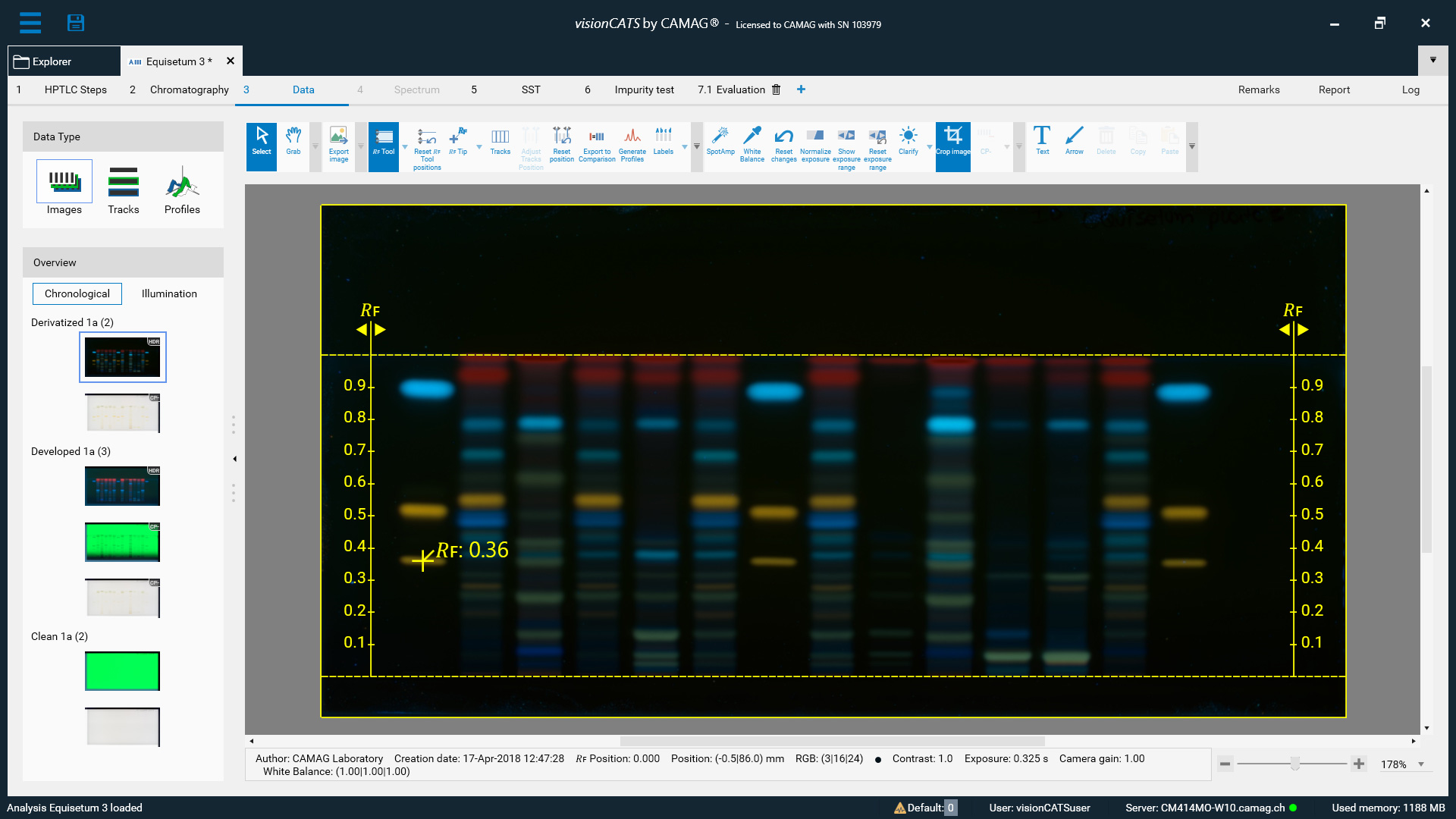

Controlled by visionCATS, the TLC Visualizer 3 can generate low-noise, high-dynamic-range images (HDRI). These images can be separated into tracks representing single samples. Any sample that has ever been analyzed can be directly compared with any other sample using the Comparison Viewer. Samples can be rearranged and compared to reference substances or samples, independent of their plate origin. Also 3D profiles of images can be generated.

The comprehensive set of Image Enhancement Tools in the Data View exploits the TLC Visualizer’s full potential. Images are automatically captured based on an optimized control of the illumination and parameters specified in the HPTLC method. Sophisticated algorithms guarantee the highest image quality for identification of even the weakest zones. The Data View allows visual evaluation of a plate in different illumination modes and offers a broad range of helpful tools, e.g. the RF tool displays the RF value of zones on the digital image, or a rectangular and/or linear zoom function.

-

Data View:

01

Data View: All data gathered through the chromatographic process can be reviewed and processed

-

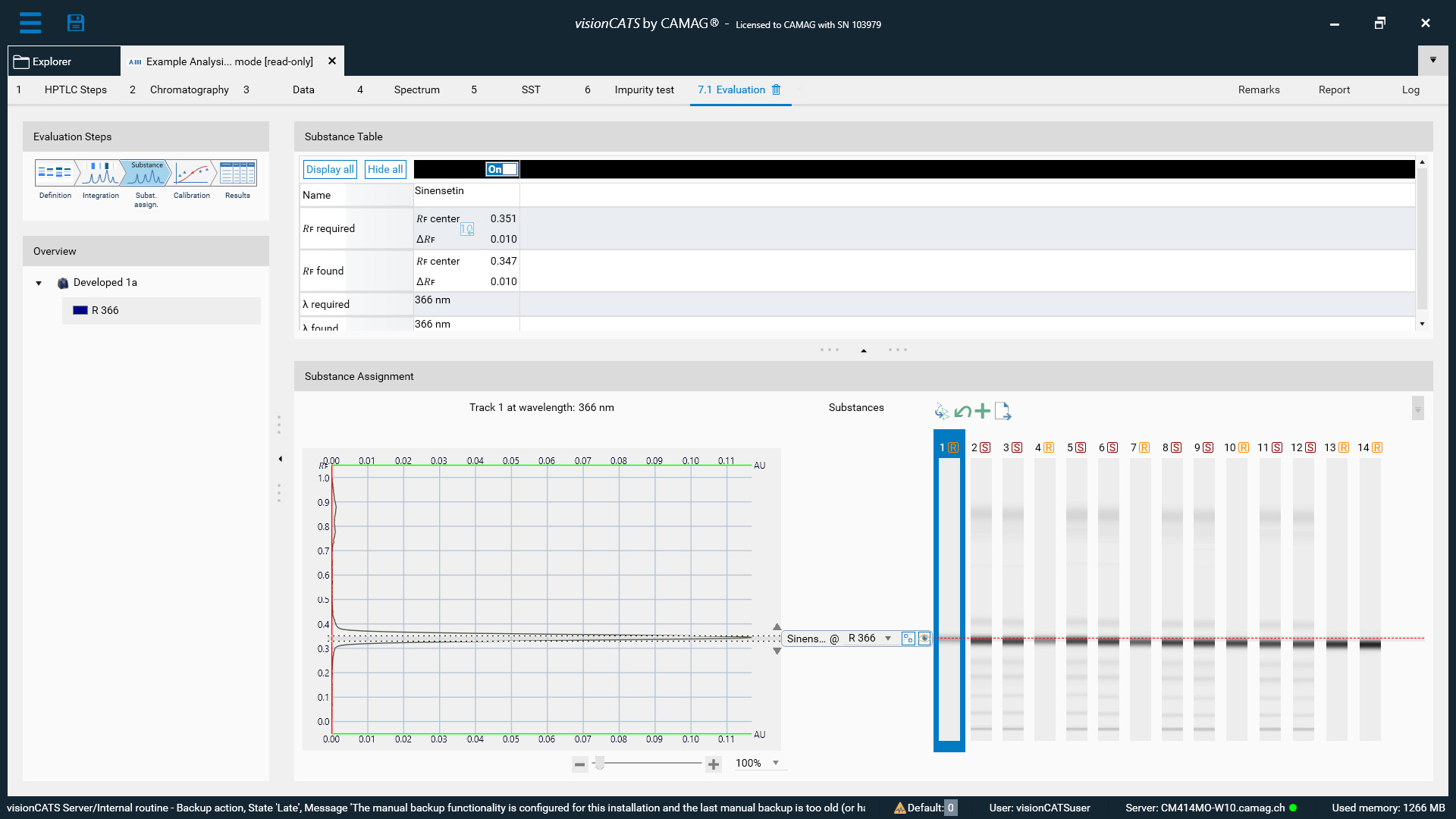

Comparison Viewer

02

Comparison Viewer: Side by side view of tracks from the same or different plates and/or detection modes

-

Image Enhancement

03

Spot Amp efficiently supports the localization of even the smallest fractions on the plate by increasing or decreasing the contrast of the zones.

Quantification with

TLC Scanner 4

visionCATS controls the TLC Scanner 4 and enables quantitative evaluation of the generated densitometric data. The spectral range of light from 190 to 900 nm is available for selecting single wavelengths for Scanning Densitometry. Detection can thus be fine-tuned to match the spectral properties of the analyte to its optimized specificity and sensitivity of the detection. For almost unlimited flexibility, several scanning steps, e.g. before and after derivatization, can be selected. Each scanning step may also include up to 31 individual multi-wavelength scans using different light sources (deuterium lamp, mercury lamp, tungsten lamp). The detection modes absorbance or fluorescence can be combined. The generated data can then be evaluated. Integration of peaks and assignment to separated substances is a matter of a few mouse clicks.

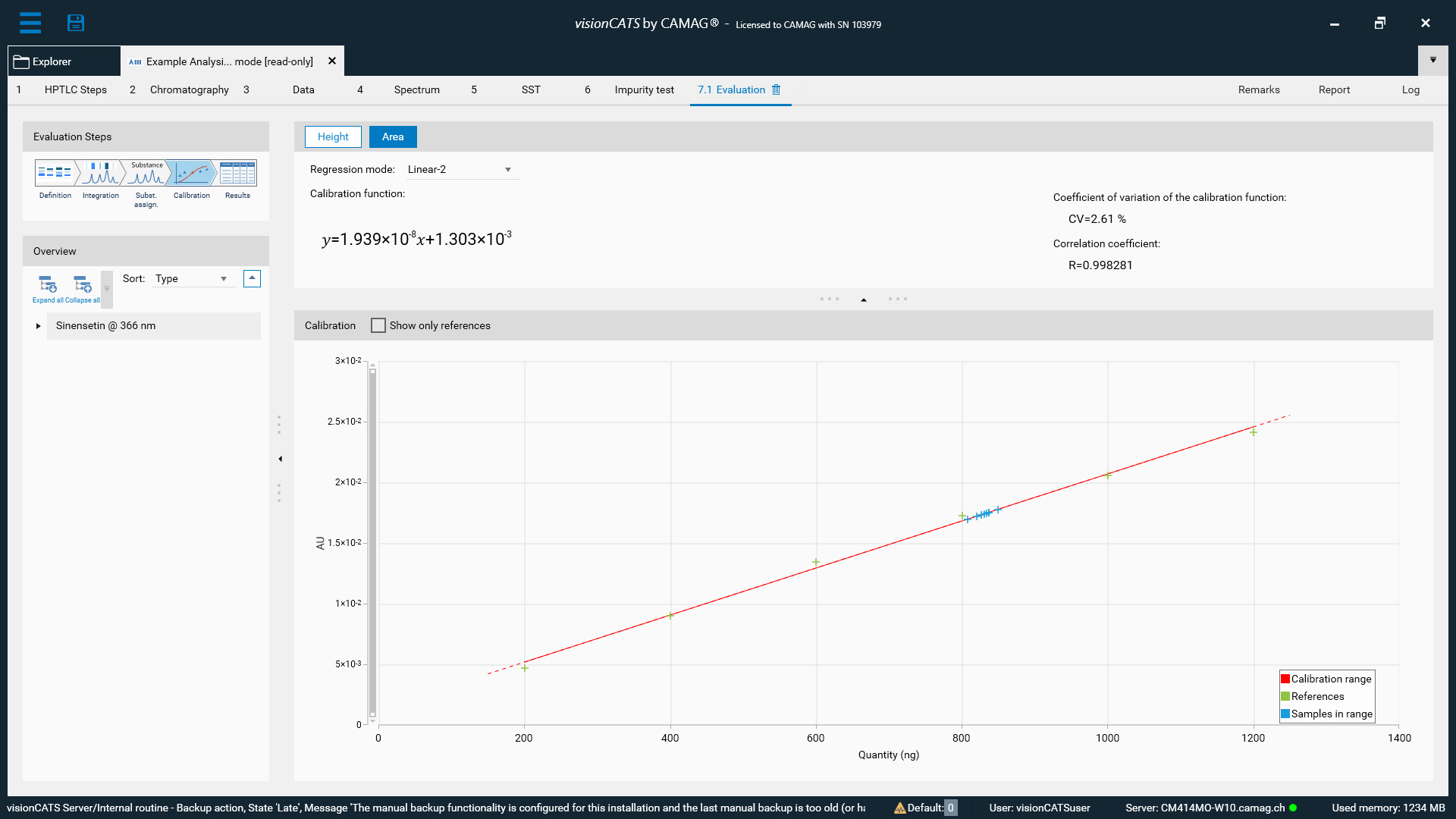

Quantification of substances can be performed via peak height or peak area. The best fitting calibration model with single-level calibration or multilevel calibration via linear, polynomial or Michaelis-Menten regression is selected. With visionCATS and the TLC Scanner 4 UV spectra can be measured as well. The selected peak positions, which are detected from a previous densitogram, are automatically scanned at the defined wavelengths. Spectra can be measured from 190 to 900 nm and displayed individually or overlaid in one diagram. Spectra recorded on different plates can be compared with the Comparison Viewer.

-

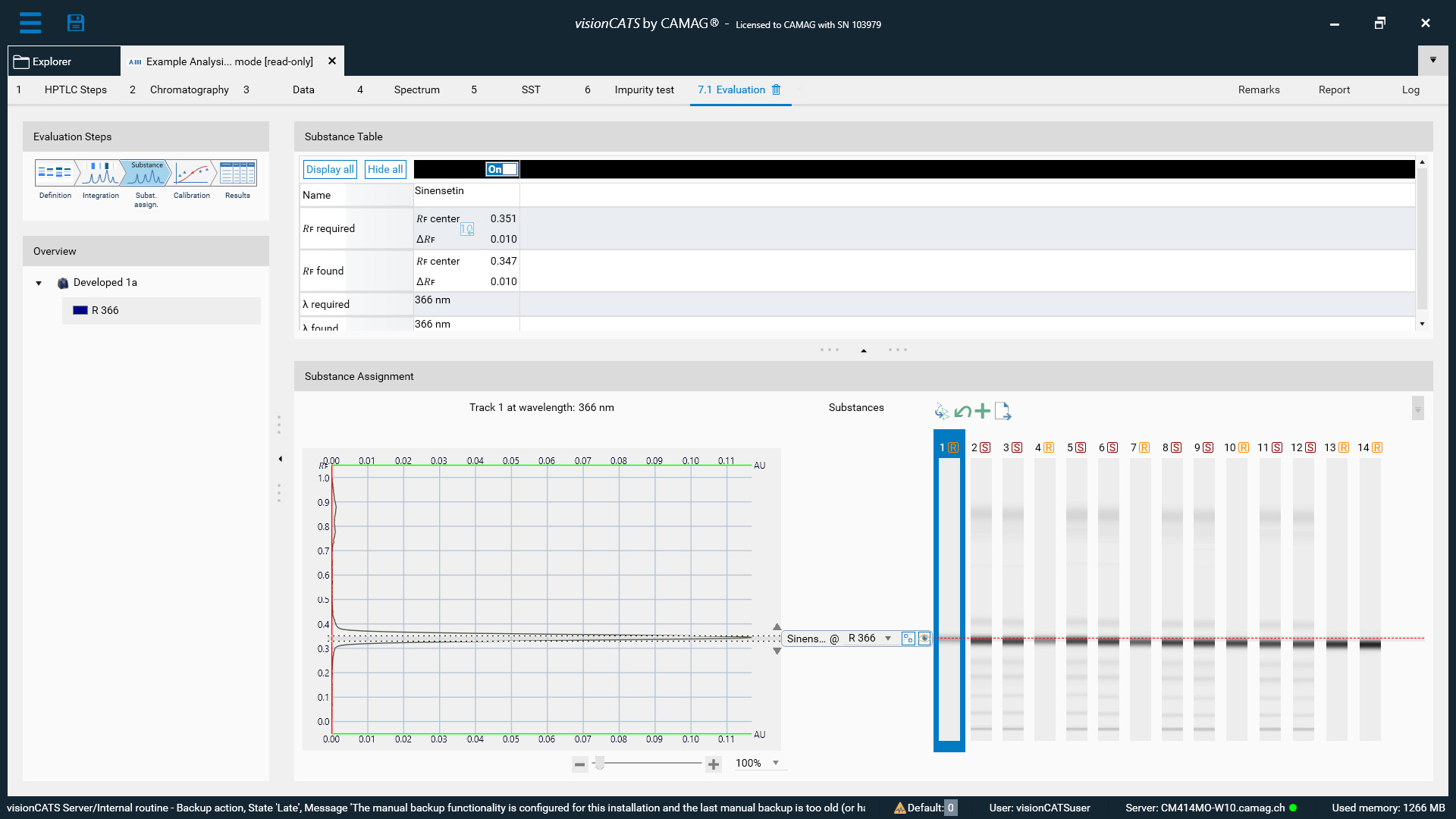

Peak Assignment

01

Peak Assignment: The separated compounds are assigned. For quantification, data from the multi-wavelength scan at the optimum wavelength for each compound is used.

-

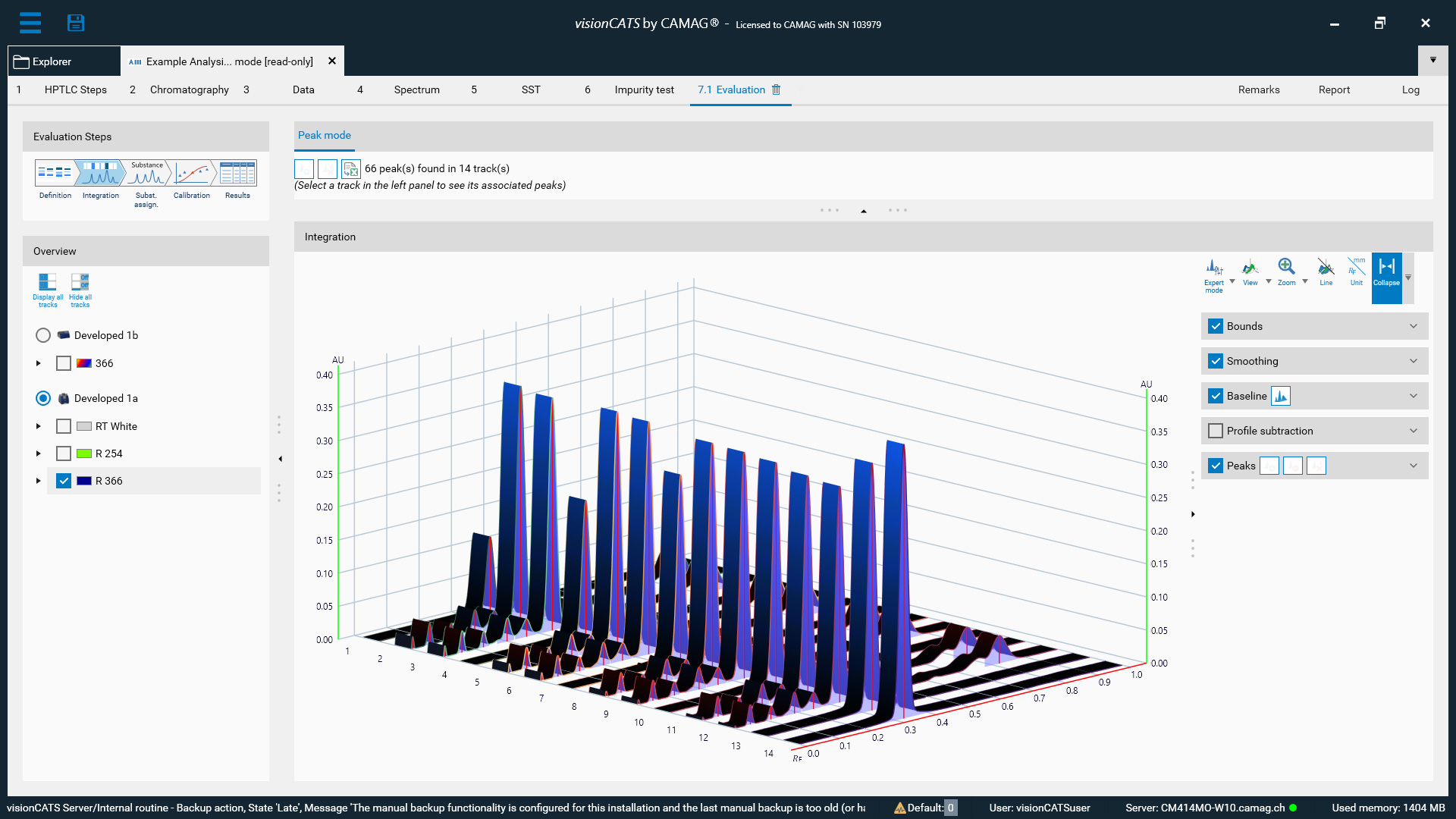

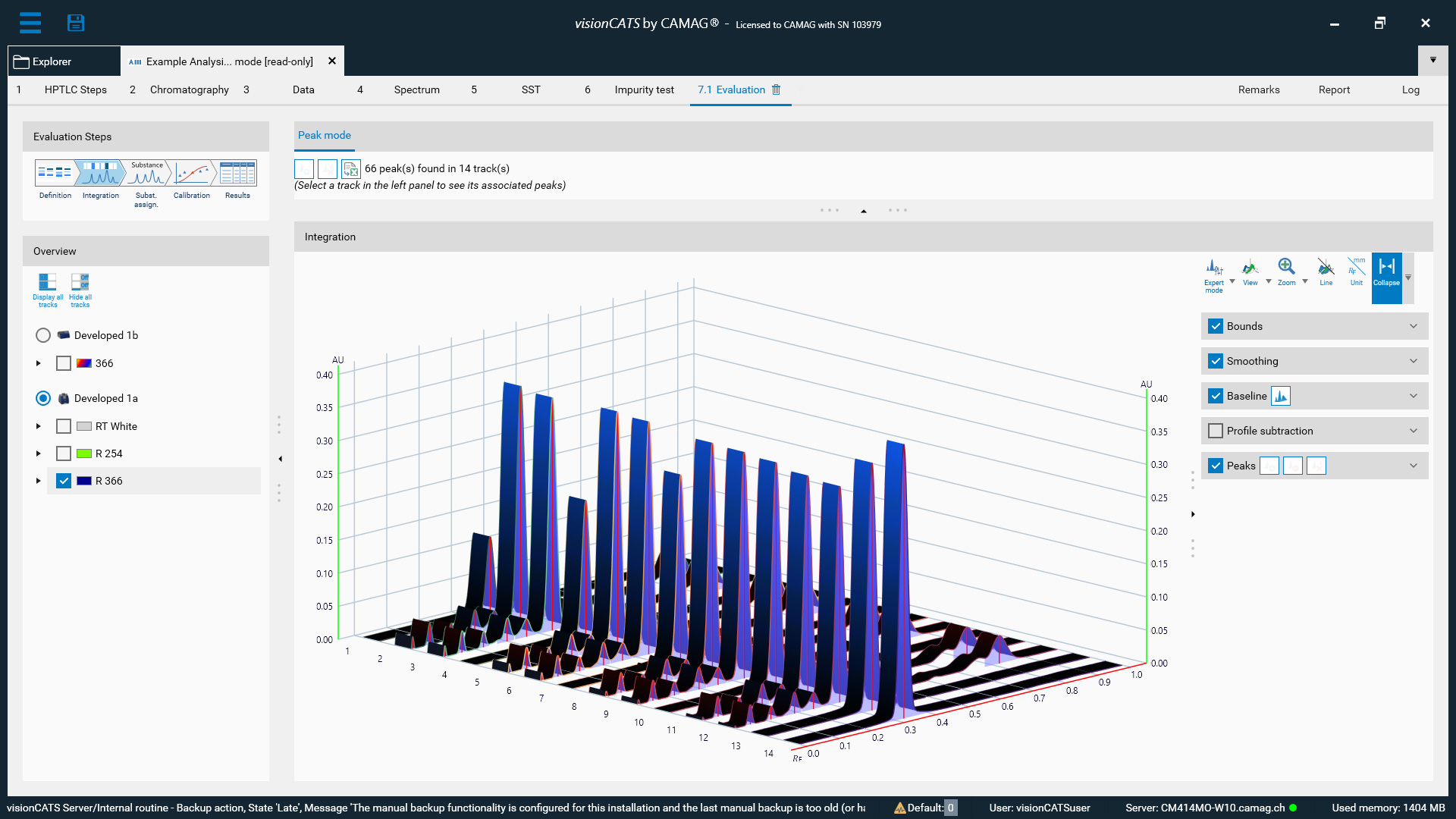

3D View and Peak Integration

02

3D View and Peak Integration: Densitograms are displayed in 3D, top or front view. Several peak integration and baseline correction settings can be selected.

-

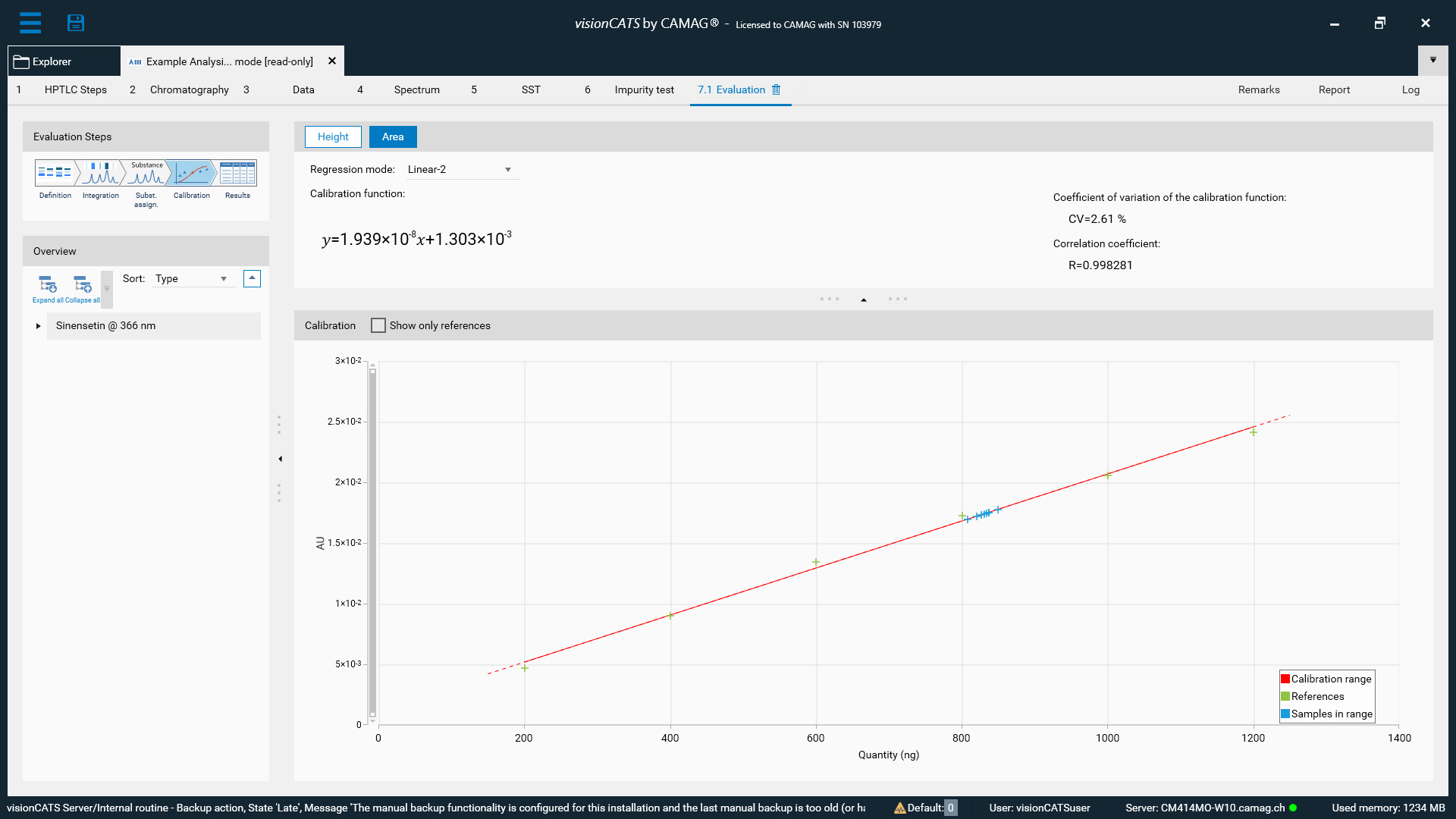

Calibration Curve

03

Calibration Curve: For evaluation the best fitting calibration model is used. Quantitation can be done via peak height or area.

database

visionCATS

Method Library

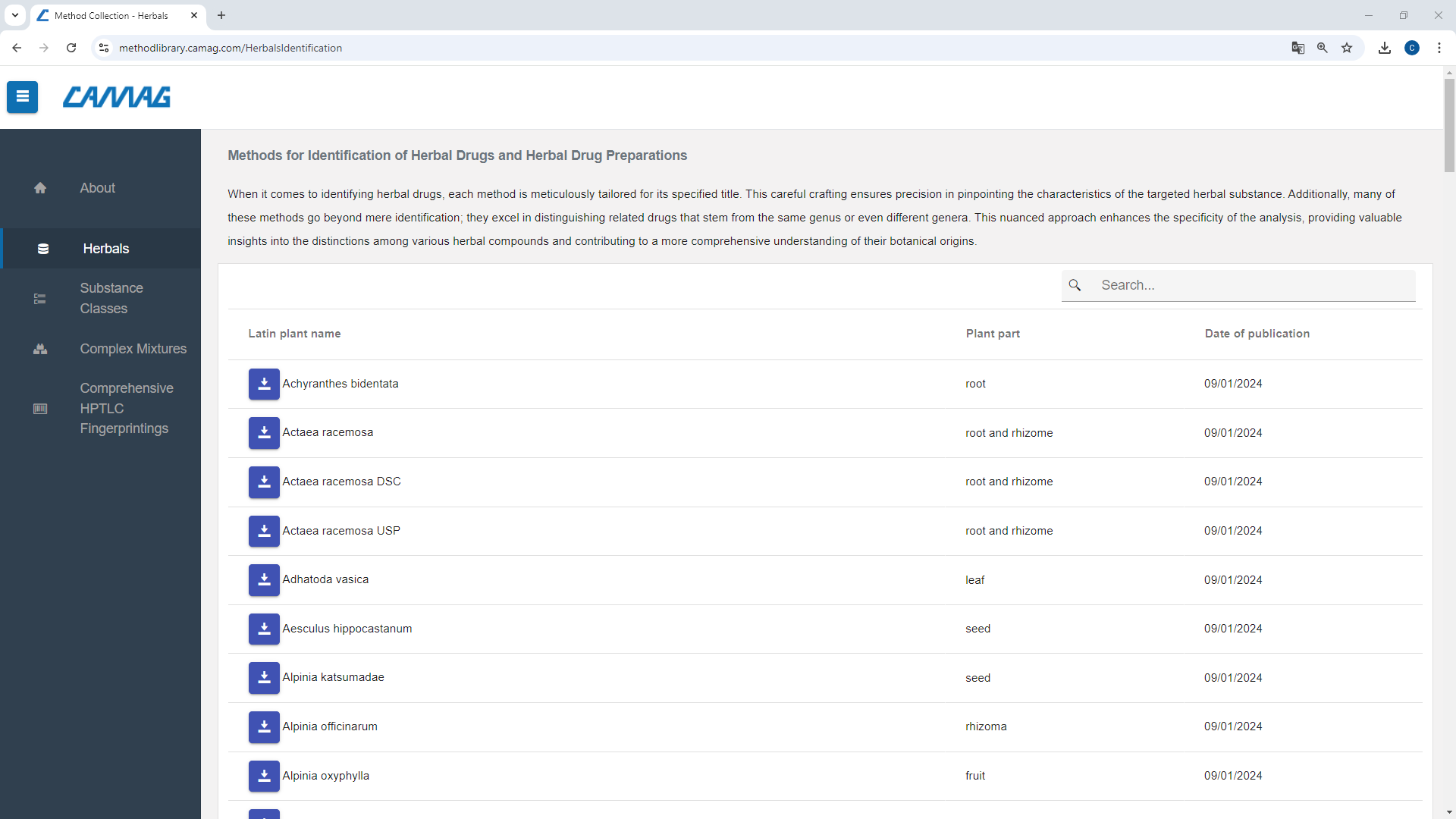

For analysts using HPTLC for identification of herbal drugs or analysis of food samples, visionCATS offers breakthrough support with the visionCATS Method Library. As a licensed visionCATS user, you can download methods from the visionCATS Method Library free of charge and import them into your own visionCATS database.

Each method includes three files:

-

A method documented in a form (e.g. docx) which may serve as an SOP and which can be easily incorporated into any quality management system. This file contains a description of the System Suitability Test (SST) and acceptance criteria for compliant herbal drugs.

-

An instrument method ready to use in visionCATS. A new analysis with all method relevant information (reference substances, plate layout, stationary and mobile phase, etc.) can then be processed. Only the Vial ID of the sample to be analyzed needs to be entered.

-

A Comparison Viewer file with reference images against which each analyzed sample can be compared and evaluated, based on acceptance criteria specified in the method document. After comparing the data of the samples with the reference images individual reports can be generated by a mouse click.

The HPTLC Method Library contains methods included in the USP Dietary Supplement Compendium and those published by the International Association for the Advancement of HPTLC. Numerous methods of identification from the European Pharmacopoeia are added as well. Additional methods will be added continually.

secure, safe, and audit-ready

-

21 CFR Part 11

The option 21 CFR Part 11 supports customers to work in a controlled environment and to establish regulatory-compliant processes. As a part of 21 CFR Part 11 compliance, electronic signature processes are available. A set of log files (System log; Method log; Analysis log; Backup log) are available to fully meet 21 CFR Part 11 requirements.

-

Qualification

For customers working in a cGMP/cGLP environment, CAMAG offers Installation Qualification (IQ) and Operation Qualification (OQ) services.

-

System Suitability Test (SST)

System Suitability Tests are used on each plate to check and ensure that the analysis was performed appropriately to produce results that are within the acceptance criteria established during method development. Only data from plates qualified by the respective SST can be directly compared. The SST is the primary tool for evaluation of data during a transfer validation. visionCATS provides several tools for setting up a SST.

-

Data Security

Data Security is achieved through access control, which is provided by a flexible, secure, and customizable User Management System and basic system settings. Users are defined with rights that determine the level of access they have. The User Management System is compatible with Active Directory. With the powerful user management, it is possible to reflect the customers’ individual safety regulations. Data are stored in a safe database to prevent accidental alteration/deletion.

-

Data Safety

The visionCATS Backup Assistant helps users to store their data into a backup file. Automatic backup tasks can be defined with the Schedule Assistant. With the Restore Assistant users can easily restore their data from the backup file.